Natural gas piping systems in residential single-family and multi-family buildings typically operate at standard delivery pressure, 1/3 pound-per-square inch gauge. Our 2 pounds-per-square-inch gauge (2 PSIG) program provides a higher-than-standard delivery pressure, helping reduce the size and cost of the natural gas piping system in new residential buildings where the distance from the meter to the first appliance is great.

Benefits

Simply put, 2 PSIG means lower costs.

Our 2 PSIG program will help you cost effectively deliver the natural gas appliances and connections residents prefer and builders know provide resident comfort, retention and lower utility bills. Generally, residential dwelling units equipped with natural gas water heating, comfort heating, cooking and clothes drying have an operating cost much lower than electric alternatives.

By delivering higher operating pressure, both the size and cost of the natural gas piping system can be reduced. As residential buildings get larger and more complex with additional natural gas appliances, the traditional method of providing the required natural gas volume is accomplished by increased pipe size. The use of 2 PSIG will allow for reduced pipe-sizing, resulting in material and labor cost-savings and efficiencies, since smaller pipe is easier to handle and install.

The 2 PSIG program is available for single-family homes, and multi-family apartment, townhouse and condominium projects in our service territory that meet all program requirements.

How to Participate

- Submit the Residential Online Application (Request for Residential Gas Service)

- Make contact with your SoCalGas planning representative before specifying any 2 PSIG system

- Download, review, fill out and submit your 2 PSIG Request Form and Agreement to your SoCalGas planning representative

- Note: Program Qualifications are listed in the 2 PSIG Agreement

- Review Installation Requirements with your SoCalGas planning representative and plumbing contractor.

Fundamentals of 2 PSIG Distribution

It's not the "pressure" that counts . . . it's the "pressure drop" that moves the natural gas inside the pipe. Piping systems in residential buildings are traditionally operated at 8-inch water column (WC) or 1/3 PSIG. By raising the pressure to 2 PSIG, several benefits become available when constructing residential dwelling units where the distance from the meter to the first appliance is great.

The pipe size is determined by the amount of energy that can be lost (also called the pressure drop) to move the natural gas, while leaving enough pressure to meet the minimum requirements of the appliance controls (usually 4- to 6-inch. WC). As the pressure goes up, so too does the allowable pressure drop that can be accommodated. The greater the pressure drop, the greater the amount of natural gas that can be "pushed" through the pipe for a given size. For a given amount of natural gas, the pipe size can be decreased as the allowable pressure drop is increased. As shown in the figure below, the amount of natural gas (934 cubic feet per hour or CFH) that can be moved through a 100 ft long - 3/4-inch pipe (operated at 2 PSIG) would require a 2-inch diameter pipe when the same system is operated at 8-inch WC.

How it Works

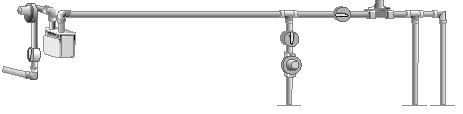

A 2 PSIG system is actually two different systems combined into one. Although each system segment is designed separately, the overall objective is to minimize the pipe sizes and reduce the cost of the installation. The 2 PSIG segment is used to bring the natural gas from the meter to each dwelling unit. In multifamily buildings and large custom single-family homes, the distance from the meter to the first appliance is much greater than that commonly found in typical single-family homes.

In many cases, this run of pipe can be 100 to 200 feet long. The use of 2 PSIG pressure will typically result in 1/2- or 3/4-inch pipe for this run compared to the 1or 1-1/4-inch pipe commonly used in low-pressure systems. Once inside the dwelling unit, a line regulator reduces the natural gas pressure to the traditional 8-inch WC. The line regulator is necessary because residential appliances are designed to burn natural gas only at low pressure.

Configuration of interior natural gas piping

There are many ways to configure the interior natural gas piping network, depending on the layout of the building, the number of appliances in the dwelling unit(s), and the location of the natural gas meter(s). The 2 PSIG program is based on SoCalGas program requirements in which each residential dwelling unit is to be served by its own natural gas meter. Each residential building is somewhat unique when it comes to designing the meter bank needed to meet this requirement as well as the other requirements listed in the 2 PSIG Agreement.

The location of the building relative to the natural gas main in the street and the property line will influence the location of the meter(s). The location and design of the meter(s), in turn, will affect the design of the natural gas piping system inside the building. The following examples are but a few of the different possibilities for multi-family buildings. The piping system can incorporate any approved piping material and/or combination of materials

Low-rise installation with header and branch lines

Low-rise installation with parallel branch lines

Basic Pipe Sizing

To eliminate any confusion, 2 PSIG natural gas piping systems can be sized using the traditional Longest Length Method in accordance with the UPC (Uniform Plumbing Code), but with a slight modification. The 2 PSIG system is broken down into two independent sections, and each section is sized separately.

1) The 2 PSIG Section

From the meter to the line pressure regulator

- Calculate the natural gas load (by adding up the name plate ratings) from all connected appliances.

- Measure length of pipe from the meter to the line pressure regulator located inside the dwelling unit.

- If there are multiple line pressure regulators, then measure the distance from the meter to the regulator furthest removed from the meter.

- The maximum allowable pressure drop for the 2PSI section is 1PSI.

- Referring to Table A for 2PSI systems with a 1PSI pressure drop, find this distance in the top row, or the next larger distance if the exact distance is not listed.

- Trace down this column until the natural gas load is found or the next larger capacity if the exact value is not listed.

- Read across the table back to the left-hand column and select the appropriate pipe size.

- If there are multiple regulators in the system, each line segment must be sized for its actual natural gas load but using the longest length previously determined above.

Parallel branch line arrangement (2 PSI section)

Header and branch line arrangement (2 PSI section)

2) The Low-pressure Section

All piping downstream of the line-pressure regulator

- Measure the distance from the line-pressure regulator to the appliance furthest removed from the regulator.

- Use this distance to size all of the low-pressure appliance runs.

- Referring to Table B for 8-inch. WC systems with 1/2 in. WC pressure drop, find this distance in the top row or the next larger distance if the exact distance is not listed.

- Trace down this column until either the appliance natural gas load or the load for that section of pipe is found; find the next larger capacity if the exact value is not listed.

- Read across the table to the left-hand column and select the appropriate pipe size.

- Repeat this process for each connected appliance or piping section.

Parallel branch line arrangement (low-pressure section)

Header and branch line arrangement (low-pressure section)

For More Information Contact New Construction

Appendix

Table A. Pipe-sizing Data

Maximum deliver capacity of pipes of different diameters and lengths in cubic feet of natural gas per hour for an initial pressure of 2.0 PSI and a natural gas of .06 specific gravity.

Table B. Pipe-sizing Data

Maximum deliver capacity of pipes of different diameters and lengths in cubic feet of natural gas per hour for an initial pressure of 7-inch water column with a 0.5-inch water column pressure drop and a natural gas of 0.6 specific gravity